Latest news

Read the latest news from the Centre for Sustainable Materials Research and Technology

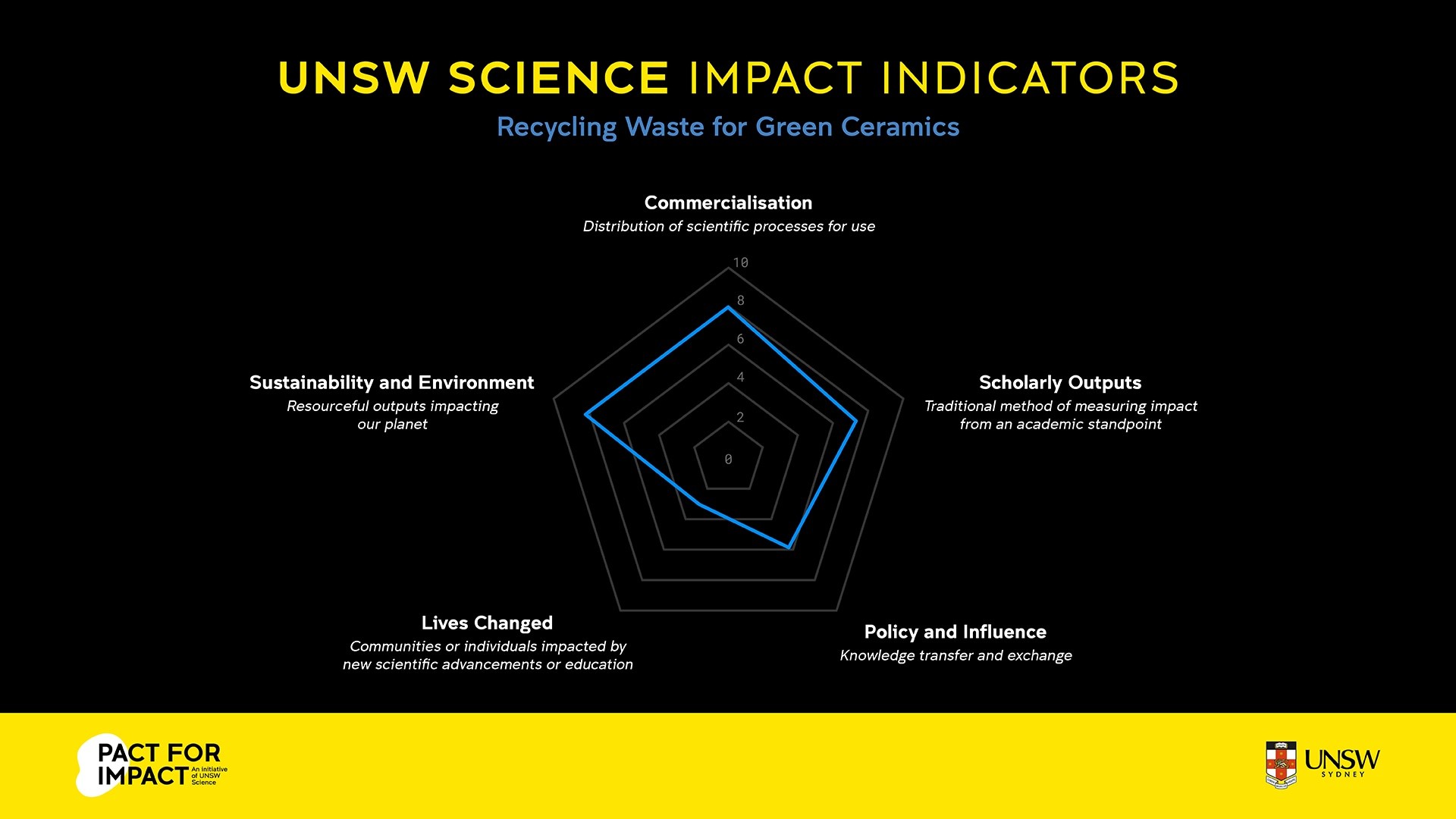

The unique collaboration between UNSW SMaRT Centre and industry partners like Shoalhaven City Council has advanced SMaRT's Green Ceramics MICROfactorieTM Technology into a commercial reality.

The collaboration spans lots of hard work to successfully reform waste textiles and glass into silicone dust-free ceramic tiles used in kitchens, bathrooms and in many built environment applications across the world.

The world and our environment is in a state of flux, and as the pressing reality of the climate crisis comes into sharp focus, we need answers.

One of the key challenges in the pursuit of a sustainable future is tackling the vast amount of waste generated by humans. And for big problems we need big solutions, and a unique partnership is taking this particular challenge head on.

“Some people may look at rubbish and see a pile of waste, but you have to look at the value within,” says Scientia Professor Veena Sahajwalla, Director of the UNSW Centre for Sustainable Materials Research and Technology (SMaRT Centre).

Prof. Sahajwalla, a leading expert in recycling science, has been working in partnership with Shoalhaven City Council and others to transform waste materials into highly-engineered, valuable products.

“Applying the science that has been developed at the UNSW SMaRT Centre, we are turning low-value materials like waste glass and textiles into high-performing and high-value products such as ceramic tiles and benchtops,” says Veena. “This is all done on a small but commercial scale at our factory on a landfill site in Nowra.”

"It’s incredible to see how tour work has resulted in real solutions, with real impact” says Veena. “We have taken mutual ownership of the problem to look for answers, whilst always valuing the science.”

Amongst the tonnes of household waste sent to landfill every year are valuable materials that have the potential to be transformed into brand-new products.

Together with her team at the SMaRT Centre, Prof. Sahajwalla developed a process that takes waste resources not traditionally used for recycling, which are often made up of complex materials, and transforms them into high-value products. She coined the process ‘micro-recycling’.

After years of development, the world’s first MICROfactorieTM was launched in 2018 harnessing micro-recycling to revive waste materials onsite, at the UNSW SMaRT Centre.

That very first MICROfactorieTM was just 50 square metres, and the perfect prototype for how other MICROfactoriesTM could be embedded into the community.

"Ultimately, a MICROfactorieTM is all about decentralisation,” says Prof. Sahajwalla. “The idea is that a small unit that couples both recycling and remanufacturing can enable communities to deal with their waste.”

The MICROfactorieTM based on the landfill site in Nowra is using the micro-recycling process to turn waste glass and textiles into stylish and sustainable ceramics that can be used for kitchen benchtops, table tops and tiles.

“We're pioneering micro-recycling here at UNSW. And our partnership with Andrew is now taking waste mattresses and creating Green Ceramics – ceramic tiles made from 80 per cent recycled materials – on a small but commercial scale.”

- Professor Sahajwalla

Full background on the Shoalhaven City Council partnership

In fact, the very fundamentals of micro-recycling pose some serious hurdles. “Everything that contains more than a single type of material, such as a mattress, gets increasingly difficult to recycle,” says Prof. Sahajwalla. “This means the commercialisation of the products we’re creating, has only been made possible once the fundamental science of micro-recycling has been understood.”

With issues that do arise, it’s important that the wider team is able to communicate to provide the best platform for learning and growing, the pair emphasise.

This story is not simply one of financial investment, but also of human investment; both have committed endless time and boundless energy to make their vision a reality.

“We've made the point that these methods are good for the environment and good for recycling. But now we’re notching up another level, one that has never been talked about in green manufacturing before, which is ‘how is it better from an operational and production point of view?’” asks Prof. Sahajwalla. “It was always assumed that if you're putting waste into manufacturing, then you must be spending more to create lower grade products, and that’s simply not the case.”

As well as contributing to a circular economy, micro-recycling actually reduces the energy requirements of 'traditional’ manufacturing by overcoming the energy-intensive extraction and processing required of natural resources.

“We’ve actually shifted the dialogue to highlight the operational benefits of micro-recycling. And the world now seems to be excited about the possibilities.”

- Professor Sahajwalla

Prof. Sahajwalla emphasises the need to think about the bigger picture.

“The world is never going to run out of waste. So, if we can keep these materials in our supply chains in a safe and a sustainable manner, then the opportunities are endless.”

The commercialisation of Green Ceramics is just the latest development in SMaRT's technology R&D.

When she reflects on the journey so far, Prof. Sahajwalla is excited about the possibilities and proud of what they have achieved.

“At the end of the day, it's cutting-edge science with environmental impact, it's safe products and it's creating local jobs. What's not to love?” says Veena.

“I am hopeful that the work we do in our partnership inspires others to consider how they can be a part of the story,”

-Prof. Sahajwalla.